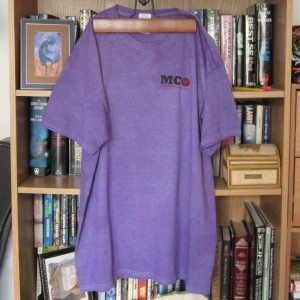

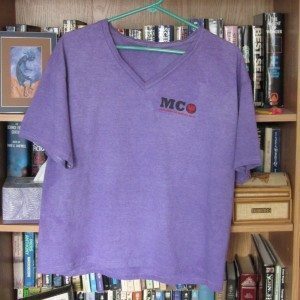

For two summers, full time before my senior year of college and half time after, I worked at an alterations shop. I learned a lot in general about clothing and construction and fitting, but there were a few specific things we did differently there than I’ve done in my sewing before and since. Every one of them improved efficiency in some way, but two are impractical now and two I simply don’t do any more. Let me tell you and you can see what you think.

Oh, and happy birthday to my mama!

1. Our sewing machines had two pedals: one knee and one foot. They were industrial machines that came this way, and I don’t know how easy it would be to retrofit a home sewing machine with such an apparatus, but one pedal lifted the presser foot and one ran the machine. To be honest I don’t remember which was which, but I assume the knee pedal ran the machine since that motion is much less fatiguing over the course of a day than working a foot pedal. Hands-free presser foot manipulation saves a lot of time over the course of a day.

2. We tenderized jeans. Hemming jeans even on an industrial machine presents its challenges, and we kept a mallet in the shop to flatten the seams before sewing. Nowadays I use a Jean-a-ma-jig (there’s a similar tool called a Hump Jumper), which works well, if slowly.

3. We used razor blades instead of seam rippers. They are WAY quicker. You want to make sure you have a sharp one so that it cuts threads without much pressure; that keeps you from accidentally slicing into the garment.  Of course you have to use it in a particular way: by pulling the two pieces of fabric apart from each other and slicing the taut threads between. For removing, say, topstitching, a seam ripper is probably still better. You do end up with a lot of loose threads, but they may not matter if the fabric is to be trimmed, and otherwise you can try the lint roller trick (not something we did in the alteration shop. I honestly can’t remember how we dealt with threads).

Of course you have to use it in a particular way: by pulling the two pieces of fabric apart from each other and slicing the taut threads between. For removing, say, topstitching, a seam ripper is probably still better. You do end up with a lot of loose threads, but they may not matter if the fabric is to be trimmed, and otherwise you can try the lint roller trick (not something we did in the alteration shop. I honestly can’t remember how we dealt with threads).

4. My favorite trick and one I will implement if I ever have a sewing space suited to it (and use my iron enough to warrant it): we had our iron cord hooked up high. I can’t remember whether it was the ceiling or high on the wall, but we had an extension cord, and from the iron the cord went upward before going through a hook and heading back down to the outlet. The cord never gets in the way or hung up on anything, or crumples your fabric by dragging against it. It’s a simple, brilliant move.

Attribution: Razor blade picture by Zephyris via Wikimedia Commons. All others via Pixabay.